Empowering Agriculture with Advanced Film Technology

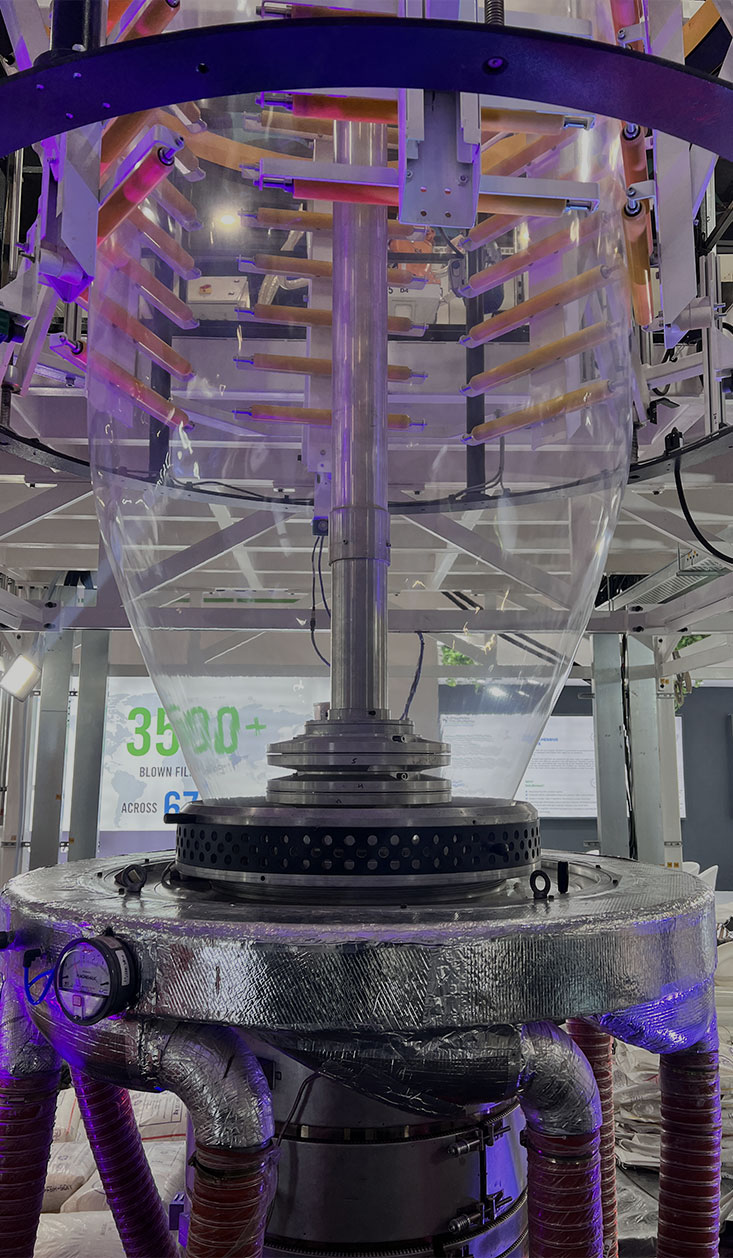

The advanced 3-layer co-extrusion blown film machines are designed for efficiency and versatility, our machines deliver high-quality, multi-layered films for diverse applications. With cutting-edge technology and robust performance, we empower industries to meet modern packaging and production demands with ease.

Uncompromising Quality: Precision-engineered components deliver optimal performance and reliability.

Tailor-Made Configuration: Fully customizable to suit your specific application and production requirements.

Connect for Mulch Film Plant Connect for Mulch Film PlantPrecision-engineered components deliver optimal performance and reliability.

Fully customizable to suit your specific application and production requirements.

The multi-layer structure provides up to 30% stronger films compared to mono-layer films, ideal for demanding applications like heavy-duty packaging.

Incorporates up to 50% recycled materials or calcium carbonate (CaCO3) in the middle layer, reducing raw material costs while maintaining quality.

Supports a wide range of polymers, including LDPE, LLDPE, HDPE, EVA, metallocene, and PP, enabling customization for specific needs.

Combines different polymers to enhance tear resistance, heat resistance, and barrier properties for applications like food and medical packaging.

Equipped with advanced features like IBC (Internal Bubble Cooling) systems, auto thickness control, and precision dies for uniform film thickness and high production rates.

Enables the use of biodegradable and recycled materials, supporting sustainable manufacturing practices.

Available in ABA and ABC configurations, with ABA offering cost savings and ABC providing multi-color and multi-material flexibility.

Our star of art IBC DIE Head is designed to maintain back pressure at peak output with Maximum overlaps Ensure excellent Melt uniformity & color uniformity over long run with Almost No dead Areas to Avoid degradation of Melt & gel generation in Long run

Ensure fastest changeover from color to Natural & Natural to color with Minimum changeover wastage

Our 3-layer co-extrusion blown film machines cater to a broad spectrum of industries, producing films for:

General Purpose Film

Surface Protection Film

Tarpaulin Film

Lamination Film

Shrink Hood Film

FIBC Liners / Mattress Covers

Food Packaging Film

LD-Shrink Film

Milk Film

Stretch Film

Courier Bags

Water Packaging Film

Atta Film

Mulch Film

Agroshed Net Film

| Parameter | Specification |

|---|---|

| Polymer Compatibility | LL/LDPE, HM/HDPE, EVA, Metallocene |

| Thickness Range | 20 – 200 microns |

| Layflat Range | 1200 – 2100 mm |

| Output Capacity | 240 – 330 kg/hr |

| Screw Design | Bi-metal screw for durability and precision |

| Die Head | Precision die for uniform film production |

3-Layer Blown Film Extrusion Machine is a game-changer for industries seeking high-performance, cost-effective, and sustainable film production. With its ability to produce stronger, multi-layered films using a variety of materials, it meets the diverse needs of packaging, agriculture, and industrial applications. Our machines combine advanced technology, precision engineering, and eco-friendly options to deliver unmatched quality and efficiency.